Understanding How Ratchet Straps Work

Published on 08/06/19

Many people find Ratchet Straps to be difficult to use and understand. Lack of

familiarity and a general misunderstanding of the anatomy of the ratchet strap

contribute to the frustration. But here at Trucking Depot, we believe that using

our straps should be easy! That is why we have written this article in which we

break down the four parts of a Ratchet Strap that you need to know about in order

to properly understand it. Once you are done with this article we hope that you are

equipped to not only use one but to understand it fully as well!

Understanding How Ratchet Straps Work

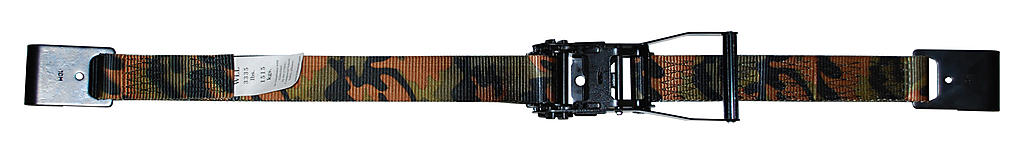

To fully understand ratchet straps it is important to go over some of the terminology and how the various parts work together to make the final product. The basic Ratchet Strap has 5 main parts that you will find listed and defined below!

Webbing – Polyester Webbing is the material used to make the “strap” portion of the ratchet strap. The webbing used for our straps is made of rigid polyester material. This material is resistant to UV rays, water, and stretching so it is the ideal strap for any outdoor hauling you may be doing. The webbing is an integral part of the whole ratchet strap because it is the most prone to wear and tear. It is important to replace the strap completely if the webbing shows any signs of damage!

Adjustable End – The part of the Ratchet Strap that is fed through the selected center slot of the tension device is called the adjustable end. The adjustable end is typically unattached from the tension device but on occasion, it is sewn to the tension device. When an adjustable end is sewn to the tension device it is referred to as captivated. Captivated Ratchet Straps are fairly uncommon because most people prefer to be able to switch out the long end if necessary. With captivated straps, the end is not replaceable so the end fitting that you have is the one you are stuck with. Captivated straps do have the advantage of never coming unattached which prevents loss.

Tension Device – The tension device is responsible for tightening down whatever load you may be securing. The device that is used in the case of a ratchet strap is called a ratchet. There is also a tension device referred to as a cam buckle. Cam buckles are typically used on lighter loads due to their lower breaking strength while ratchets are used on larger loads because of their sturdy construction. The advantage of cam buckle straps is the easiest way tie-down straps can be tightened. They act almost like a belt and one pull can do the trick if used correctly. Ratchets, on the other hand, are much harder to use and are tightened with a ratcheting motion that locks the load insecurely. We have a variety of different tension device hardware options on our site with size and material customizations available.

Fixed End – The fixed end of a ratchet strap is the section that attaches to the tension device. This section is also sometimes referred to as a short end because it is almost always the shorter of the two ends. Our in-stock short ends are usually either 8 or 12 inches, but we can cut them to any length that you might need!

End Fittings – The piece of hardware that attach the ends of your strap to the tie down point is called an end fitting. These end fittings come in many shapes and sizes and can accomplish many different purposes. Hardware like flat hooks is mainly used in the flatbed industry. S hooks and wire hooks are used for hauling small recreational vehicles. Snap hooks are used for automobile hauling. And E Track fittings are used in moving trucks, semis, and trailers. These are just a few of the broad uses for end fittings, but the list goes on and is growing constantly. You can even mix and match hardware if your job requires a special kind.

The Best Ways to Store Away Your Tie Down Straps

Now that you know the terminology a little bit better, we would like to discuss a few techniques that you can use to extend the life of your ratchet straps! Following these steps can greatly increase the life of your tie down straps!

Proper Storage – The first, and most common, mistake that people make when dealing with their ratchet straps is improper storage. Many people do not realize how damaging it can be to store them improperly. The polyester webbing is resistant to UV Rays and water, but that does not mean it cannot be affected by it at all. Long-term exposure to sunlight and water can greatly reduce the strength of the webbing. While it may seem insignificant, the reduction of strength can cause serious damage to you and your load. Ratchet straps should always be stored in a dark, dry place away from outside elements. Our Trucking Depot Duffel bags are great for storing straps and keeping them from harmful elements. Socks, Ziplock bags, rubber bands, and zip ties are also common methods for organization and storage.

Proper Usage – Ratchet straps are an extremely versatile tool and can be used in so many different ways! The unfortunate thing is, many of the uses are harmful to the straps and just plain dangerous. When using ratchet straps to haul something that may have sharp edges, it is important to use corner protectors of some kind. If you do not use any kind of protector to serve as a barrier between your strap and your load, you could cause serious damage to your strap and possibly cause it to snap completely. The wind at high speeds will cause the strap to vibrate which can make it rub up against whatever it may be securing. If your straps do become damaged DO NOT continue to use them. Throw them away and get new ones as soon as possible!

Proper Inspection – This point goes right along with the previous point about proper usage. Since a damaged strap could equal a catastrophe it is important to know when your straps may be defective. That is why it is extremely important to inspect your straps before and after every trip and at many stops along the way. Any visible signs of damage such as burns, cuts, snags, and holes all warrant the immediate replacement of the damaged area. If you were to lose your load during transit because of a broken or damaged strap you would be completely liable whether you knew about it or not. Not only could you cause a serious accident, but you would also face massive fines and possibly even jail time. These are all reasons that you should inspect your ratchet straps as much as possible!

How to Understand the Ratchet Strap Limitations

Breaking Strength – The breaking strength of an item is the amount of stress that it can withstand before ultimately failing. Every element of the Ratchet Strap has its breaking strength from the hardware to the webbing to the end fittings. The breaking strength of all the parts as a whole is used to calculate the Working Load Limit for the strap so it is important to get an accurate calculation. Since we know that the weakest point of the strap will be the point where it breaks first, we will use the weakest part of the strap to determine the breaking strength of the whole ratchet strap. For example, if we had webbing, hardware, and end fittings that were all rated for 5,000 pounds, the overall breaking strength would be 5,000 pounds. However, if the breaking strength of the end fittings were 3,000 pounds, the overall breaking strength would be reduced to 3,000 pounds.

Working Load Limit – Once we have determined the breaking strength we then take 1/3 of that number to determine the Working Load Limit. As we know, cargo does not always stay perfectly in place as we want it. Whether it is an unexpected stop, road debris, or a dangerous driver, unexpected and abrupt stops or movements can happen, causing our load to shift and move. Working Load Limit is designed to take these movements into account. Working Load Limit is the number that ultimately determines which type of strap we use.

According to the Department of Transportation, the aggregate Working Load Limit of whatever you are using to tie down must equal at least 1/2 of the weight of whatever you are securing. For example, if a load weighs 10,000 pounds you would need a total Working Load Limit of 5,000 pounds at minimum to safely secure the load. Every piece of our equipment is thoroughly tested and built with careful consideration so you can be confident in the ratings that are given. Proper The Working Load Limit is enforced by the Department of Transportation and failure to abide by the guidelines given could result in heavy fines and possible jail time depending on the state. DO NOT use your ratchet strap if the Working Load Limit the label is missing!

Safety Using Ratchet Straps is the Number One Priority

Use common sense when you are preparing to use your ratchet straps. If you have a bad feeling about something or think that your strap may not be able to get the job done, you are probably right! It is better to spend a few bucks on a new strap than it is to use a defective strap and put everyone on the road in harm’s way because you didn’t want to wait. To do so would be selfish and dangerous. Remember to always inspect your straps before every use, follow the Working Load Limit on the label and store them properly while they are not in use.

If you have any questions or concerns about the content of this article please give us a call at 800-444-0956! Our experts would be more than happy to help you and get you the information you need to safely use your ratchet straps!

Make sure to check out some of our products used in today’s post!

Tie Down Straps

Ratchet Straps

Shippers Supplies Duffle Bag

Tie Down Webbing