The Differences Between E Track and L Track Rails

Published on 06/28/19

Today we will be going over the main differences between E Track and L Track Rails and helping you decide which one fits your application needs best.

E Track vs. L Track

E Track and L Track are both extremely versatile tools in the cargo control industry. Today we will be talking about the differences between the two securement methods and how you can make them work for you!

L Track

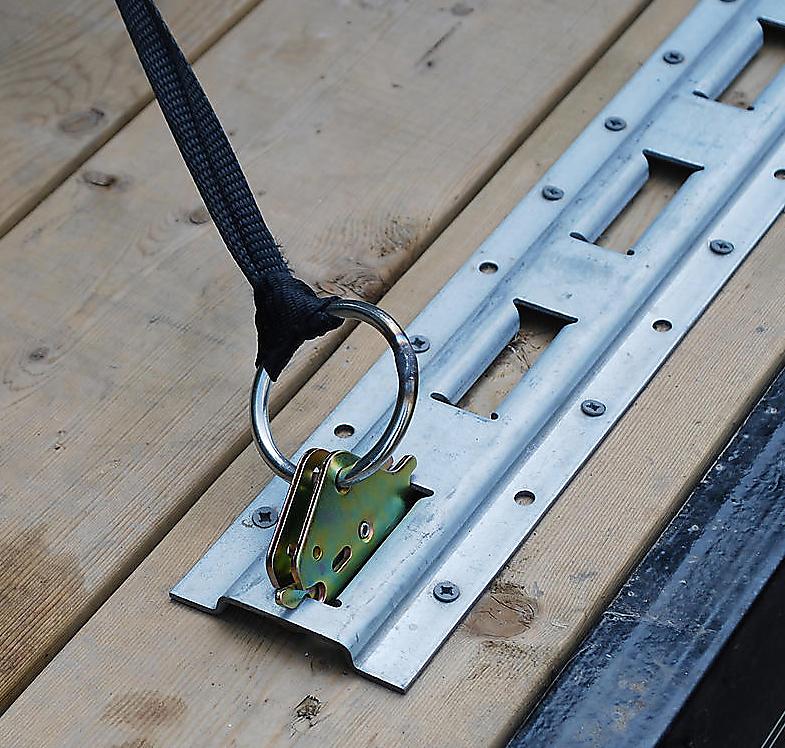

L Track, which is also referred to as airline track, first gained popularity in the airline industry. The low-profile design of the L-track was used to secure the seats in the aircraft to the floor. The design of the L track allowed the seats to be rearranged quickly which resulted in its growing popularity. As time has progressed, L track has made its way into the ground transportation industry.

L Track is also useful for securing wheelchairs. Many handicap-accessible vehicles are installing L Track for quick and easy securement of wheelchairs. Some companies even make retractable ratchet straps that ensure the wheelchair and its passenger stay secured for the whole ride! L Track has also started making its way into the recreational vehicle market. ATVs, Motorcycles, Dirt Bikes, and UTVs are all being secured by this low-profile, yet sturdy securement system.

L Track is also used for sprinter vans and other types of cargo vans. The variety of attachment points and attachment types make L Track a very useful tool to have in any transport vehicle. Some semis are even using L Track to secure their cargo.

The low profile and simple design are what draw many people toward L Track. The transportation industry is constantly looking for better and more efficient ways to transport cargo and L Track is another one of those ways. The sleek design, simple installation, and relatively affordable prices make them perfect for the transportation industry!

L Track is constructed from heavy-duty aluminum. The Track rail itself has a breaking strength of 1,600 pounds. The L Track rails come with pre-drilled holes for mounting purposes and can come in multiple different lengths. For every inch of E Track rails, there is a mounting point. This gives the user plenty of space to work with for mounting different types of cargo securement methods.

You may not be using L Track for industrial purposes and that is fine but you may be thinking that the L Track rail might not fit where you are wanting it to.

You may be thinking that you donʼt need that many attachment points. For that, you will want to take a look at our L Track Anchor Point. The anchor point combines convenience and durability into a small, two-inch attachment point that works exactly like a regular L Track rail! Just bolt the anchor wherever you want and you will have your own Mini L Track rail!

E Track

Over the last decade, E Track has taken the transportation industry by storm. There are so many drivers that use E Track ranging from commercial trucking in tractor-trailers to recreational hauling in enclosed trailers. Its success can be attributed to its simple design, easy installation, and endless customizability. There is a multitude of attachments that can be used to secure cargo using the E Track system. E Track rails are installed on the floors, walls, or both, and then used for a variety of different purposes. E track on the floor is most commonly used for securing some kind of vehicle to the floor using axle straps or over-the-wheel auto straps. There are other uses for the floor E Track as well but that would be considered the main use.

E Track is used on the walls primarily for strapping loads to the wall to prevent load shift or for hooking up a load bar to keep large items from tipping or falling with sudden movements. Users can install either Vertical E Track or Horizontal E Track. The E-fitting slots on Vertical E Track run parallel to the rail itself and have 1 slot for every 4 inches of E Track rail. The Horizontal E Track has 1 E-fitting slot every 2 inches of E track rail. The slots on both the vertical and the horizontal are compatible with all E-fittings.

The rails are made from solid 12 gauge steel and are capable of hauling heavier loads that L Track might not be able to handle! E Track is known for its simple connection and disconnection and its versatility as a tie-down system. This simplicity has helped it become a staple of the trucking and transportation industry!

Is E Track or L Track Better?

When you compare the two side by side it is hard to differentiate which one is better and it ultimately comes down to personal preference. Each one has its pros and cons and it depends on what kind of securing you are gonna be doing. As long as you follow the safety warnings and do not exceed the breaking strength or Working Load Limit of any of the products you buy, either one of these products will get the job done for you!

You can view the products used in today’s blog by clicking any of the products below.

E Track

L Track

Vertical E Track

Horizontal E Track

You can view some of our other E Track or L Track Blogs by clicking any of the below blogs

Everything You Need To Know About E Track

Top 5 Alternative Uses for E Track

If you have any questions regarding any of our L Track or E Track Rails you can contact our experts by using our online contact form located at the top of the website if you prefer communications via email. You can also reach our Trucking Depot experts by calling us at 800-444-0956 for further information today.